|

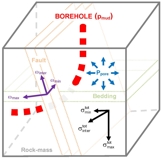

Factors in the rock mass that influence the borehole stability |

|

|

|

|

|

|

Loading conditions

|

|

, ,

, ,

|

Total in situ stresses

|

|

|

Pore pressure

|

|

, ,

, ,

|

Pore pressure effectivenesses

|

|

|

Mud pressure (in the borehole)

|

|

|

|

Further relevant factors |

|

|

|

●

|

Borehole wall condition (permeable, impermeable, or cased)

|

|

●

|

Orientation of the borehole and of perforations

|

|

●

|

Orientations and properties of faults and bedding planes

|

|

●

|

Deformation properties and strength of the surrounding rock

|

|

|

|

|

|

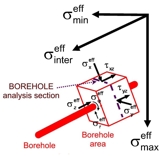

Stresses around a borehole |

|

|

|

|

Primary in situ

stress state

|

|

|

Effective stresses

in the rock mass

|

|

|

Effective stresses

parallel and perpendicular to the borehole axis

|

|

|

Shear stresses parallel

to the borehole axis

|

|

Secondary stress

state around openings

|

|

|

Effective stress

radial to the borehole wall

|

|

|

Effective stress

tangential to the borehole wall

|

|

|

For a borehole aligned parallel to an in situ principal effective stress the normal

stresses perpendicular and parallel to the borehole alignment are identical

with the effective principal stresses in the rock mass and there are no

shear stresses in that direction.

For a boreholealignment deviated from the orientations of the in situ principal

effective stresses results in different magnitudes and orientations of the

normal stresses in relation to the borehole and in shear

stresses parallel to the borehole axis.

A modified borehole

orientation can result in a different failure mechanism. |

|

|

|

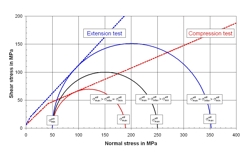

3D Stress configuration and strength (GLAST) |

|

Description of the

load dependent strength with the Mohr-Coulomb criterion

|

|

|

|

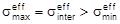

Compression test ( ) )

→ too

pessimistic

Extension test ( ) )

→ too optimistic

|

|

|

|

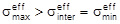

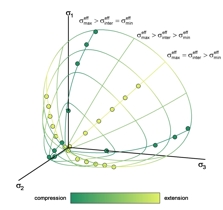

Description of the load dependent strength with the Tauber criterion

|

|

|

|

|

|

Collation of the strengths under any 3D stress states in an envelope surface (characterized

with only three parameters).

The strengths used to

define the failure envelope are determined in compression & extension

tests.

|

|

|

|

Use of

the “classical“ Mohr-Coulomb rock strength criterion for borehole stability

analyses can result in considerable reduction of the reliability assessment;

the Tauber failure criterion defines the strength under 3D stress

conditions (GLAST), which largely excludes the uncertainty in many current

assessment approaches.

|

|

|

|

Identifying zones of instabilities |

|

|

|

|

|

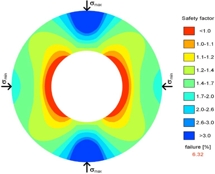

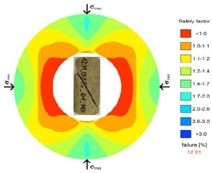

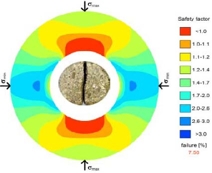

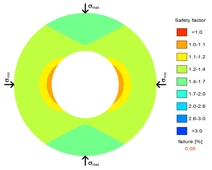

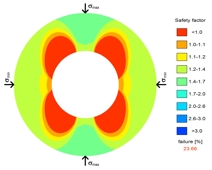

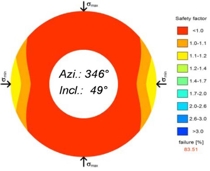

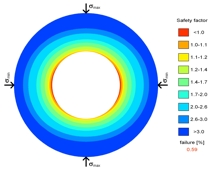

The relative positions

of the failure envelope and the current 3D stress state define the Safety

Factor.

A Safety Factor ≤ 1 shows that the strength has been reached or exceeded and this could mean that macroscopic failure/sanding occurs in that region.

|

|

|

|

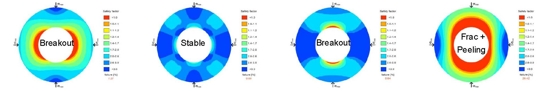

The

overall stability assessment around the borehole is illustrated with a

colour corresponding to the Safety Factor. This shows the radial and

tangential extent of unstable regions.

Special

evaluations of the stress conditions around the borehole wall, and of their

3D orientations, are used to assess the type of failure.

|

|

|

|

Common types of failure |

|

|

|

|

|

Breakout (shear failure)

Cause: Critical normal stress deviator around the borehole wall.

Propagation: Usually in the direction of the minimum, but possibly also in the direction of the maximum far field stress component perpendicular to the borehole axis.

|

|

|

|

|

|

Frac (tensile failure)

Cause: Critical tangential tensile stress in the borehole wall.

Propagation: In direction of the maximum far field stress component perpendicular to the borehole axis, with the minimum stress component as the frac surface normal.

|

|

|

|

Influence of planes of weakness on the borehole stability |

|

|

|

Borehole in undisturbed rocks

|

Borehole parallel to a plane of weakness

|

|

|

|

|

|

|

|

Borehole trajectories closed to or parallel to the orientation of zones/planes of weakness increase the risk of instabilities.

|

|

|

|

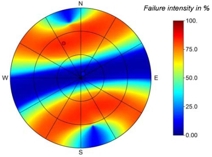

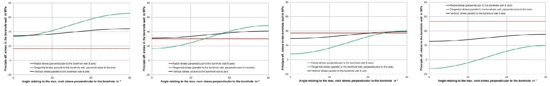

Causes of failure in deviated boreholes |

|

|

|

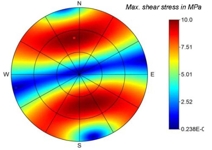

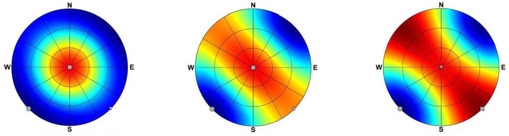

Trajectory & failure intensity

|

Trajectory & shear stresses

|

|

|

|

|

|

|

|

Instabilities in boreholes deviated from a principal stress axis can result from critical shear stresses parallel to the borehole axis, especially in the direction of the largest difference between the maximum and minimum far field stress components.

|

|

|

|

Effects of shear stresses parallel to the borehole axis |

|

|

|

|

|

Critical

shear stresses parallel to the borehole wall result in breakout &

peeling.

A critical normal stress deviator is not necessarily required.

|

|

|

|

3D in situ stress state and borehole stability |

|

|

|

|

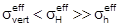

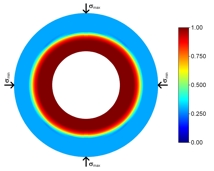

Spatial effective stress

magnitudes (dark blue → min, dark red → max)

|

|

|

|

|

|

|

|

|

|

|

|

Failure intensity in the near

borehole zone (dark blue → min, dark red → max)

|

|

|

|

|

Different intermediate principal stress magnitudes, even with unchanged maximum and minimum stress components, can lead to very different failure intensities.

|

|

|

|

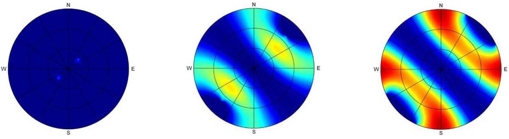

Failure affected by MOPP+

(see 3D Biot coefficient) |

|

|

|

Initial pore pressure effectiveness

|

Initial borehole stability

|

|

|

|

|

|

MOPP+ & pore pressure effectiveness

|

MOPP+ & borehole stability

|

|

|

|

|

|

|

Loosening, particularly in low porosity rocks, increases the pore pressure effectiveness (MOPP+), and thus changes the effective stresses. This can lead to a time-dependent propagation of failure and to increasing borehole instabilities..

|

|

|

|

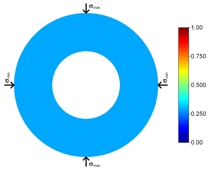

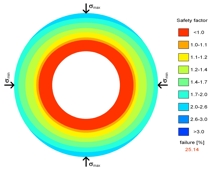

Optimization of drilling parameters (e.g. mud pressure) |

|

|

|

low

|

optimal

|

high

|

very high

|

|

|

Stress in

the borehole wall (red - radial stress,

green - tangential stress , black - paraxial stress)

|

|

|

|

|

Stability around the borehole (red - Zone of instability)

|

|

|

|

|

With an appropriate collation of individual stability analysis results, further analyses can be made of the trend of the development of instability (for example resulting from varying mud pressure, borehole alignment, etc.).

|

|

|

|

Summary of borehole stability |

|

|

|

The borehole stability is (in addition to technical and technological parameters) affected by rock mechanical boundary conditions. They have very different, partly opposing effects with respect to the risk of failure. But this can be evaluated with expert rock mechanics analyses, and can therefore be mitigated.

|

|